High-Performance Crushing System Components for European Wood Chippers

We specialize in manufacturing precision wood chipper crushing system components for leading European OEMs and suppliers. Our core expertise lies in producing cutter discs/drums and feed rollers using premium Q345B low-alloy high-strength steel, with customizable outer diameters ranging from 700mm to 1000mm.

Our Core Manufacturing Capabilities

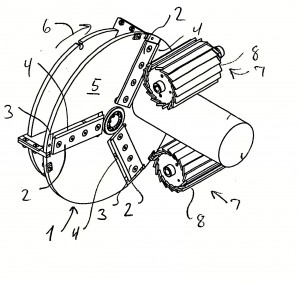

1. Custom Cutter Disc/Drum Production

- Diameter Range: 700mm – 1000mm (other sizes available upon request)

- Blade Configuration: Optimized blade count, arrangement, and geometry based on material processing requirements

- Cutting Angles: Scientifically engineered angles to maximize efficiency and service life

- Material: Premium Q345B steel with excellent strength-to-weight ratio and impact resistance

2. Heavy-Duty Feed Rollers

- Precision-engineered to match cutter drum specifications

- Designed for smooth, consistent material feeding

- Custom surface patterns and drive configurations available

- high-quality 42CrMo NM400 construction for durability

Technical Advantages

Superior Material Selection – Q345B Steel

- High yield strength (≥345 MPa) for demanding chipping applications

- Excellent toughness and fatigue resistance

- Good weldability and machinability

- Meets European machinery safety standards for material requirements

Advanced Manufacturing Processes

- CNC machining for precise dimensional accuracy

- Professional heat treatment for enhanced wear resistance

- Dynamic balancing testing (ISO 1940 standards)

- Surface hardening treatments

- Comprehensive quality control at each production stage

Why European OEMs Choose Our Components

1. Performance-Oriented Design

- 30% longer service life compared to standard components

- 20-35% higher throughput efficiency through optimized blade geometry

- Reduced vibration and noise levels for smoother operation

2. European Market Compliance

- Experience supplying to major European wood chipper brands

- Understanding of CE marking requirements and EN standards

- Flexibility for small to medium batch production

3. Cost-Effective Manufacturing

- Direct manufacturer pricing (no intermediaries)

- Competitive lead times

- Technical support throughout product lifecycle

- Spare parts availability

Quality Assurance

- ISO 9001:2015 certified manufacturing facilities

- Full material traceability

- Dimensional inspection reports provided

- Performance testing before shipment

- Sample approval process available

Applications

- Industrial wood chippers

- Forestry equipment

- Landscaping and waste management

- Paper/pulp industry

Request a Quote or Technical Consultation

Contact us today for competitive pricing, technical specifications, or to request samples. We welcome OEM partnerships and provide dedicated engineering support for custom projects.

Post time: Dec-16-2025